OUR SUPPORT FOR YOUR SUCCESS

discover our services

The company aims to satisfy the expectations of its customers by offering them a service of high technological content, which is however at the same time adapted and customized to their particular needs in such a way as to activate a relationship of collaboration and mutual cooperation.

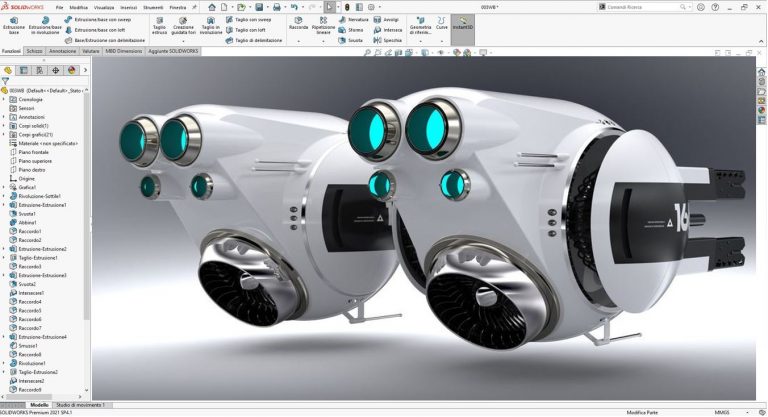

Project design & managing

Through the knowledge of both traditional and innovative production processes, combined to the ability in 3D design softwares, product feasibility, analisys and prototiping we are able to develop projects from the idea to the realization.

We also have a network of competent suppliers capable of industrializing the product.

3D laser scanning & probing

We rely on the most consolidated 3D scanning technologies to have confidence in the result. 3D scanning and probing are the starting point or the end point of a quality and confident production process. For this reason we are constantly updated on hardware, software and staff training.

We believe that there is no better technology than another but every object needs the most appropriate scanning technology and the correct approach to work.

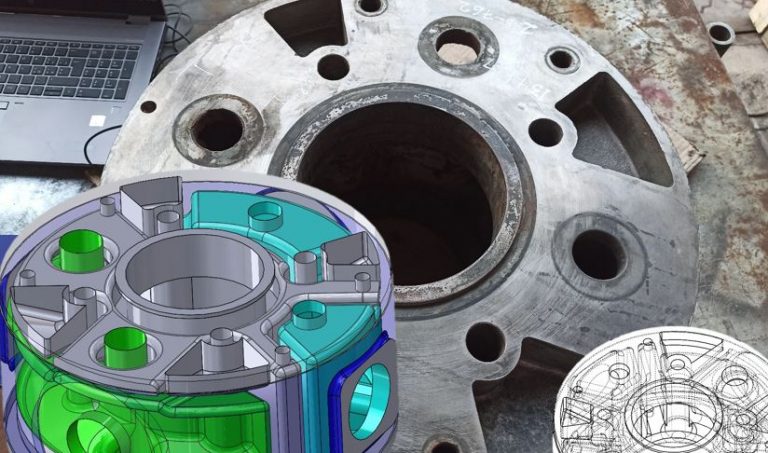

Reverse engineering

Where spare parts are needed for which construction drawings and processes are not available, reverse engineering is the solution. Reverse engineering is often not a way to “copy” something that already exists, but the starting point for modifying and improving it.

Reverse engineering is the 3D design and evaluation of materials, tolerances and the manufacturing process. Relying on reverse engineering professionals means relying above all on someone competent in production processes.

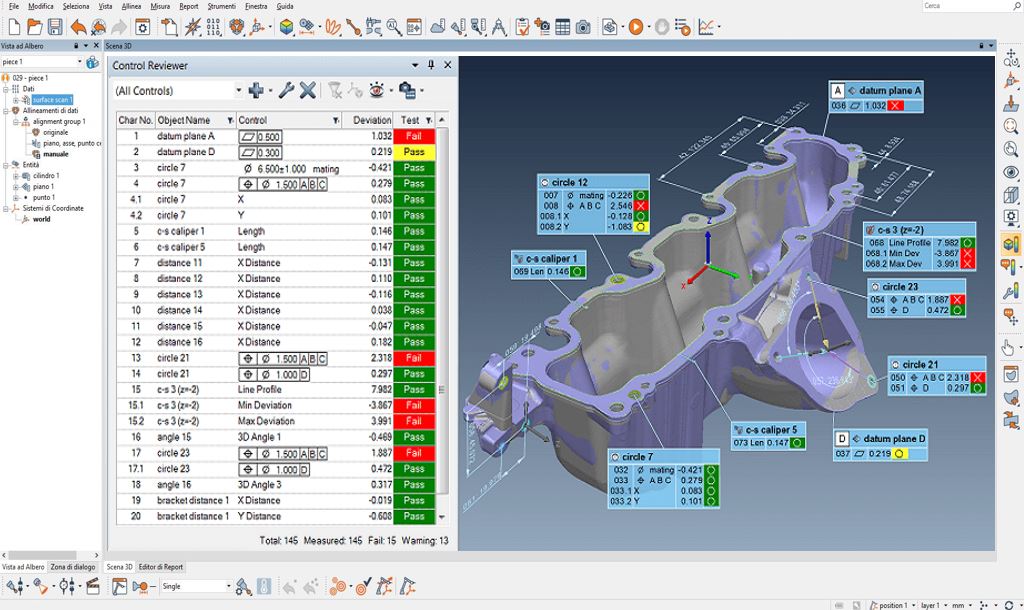

Quality control & Report

Checking the quality of an object means evaluating the way it was made.

3D scanning or probing, superimposed on the ideal design model, allows the evaluation of geometric deformations. Often the quality control ends only after the identification of the possible cause of the defect. Reports are used to track identified defects over time and evaluate the improvement or worsening of a production process.

Software & Methods training

The mastery of the use of the software is considered the fundamental basis for any good project.

For this reason, it is important to rely on qualified personnel with experience in the sector for training. The Solid Energy team boasts among the most prepared trainers, so much so that it is the point of reference for the technology producers themselves.

The team of designers is the same team of trainers to ensure consistency and effectiveness.

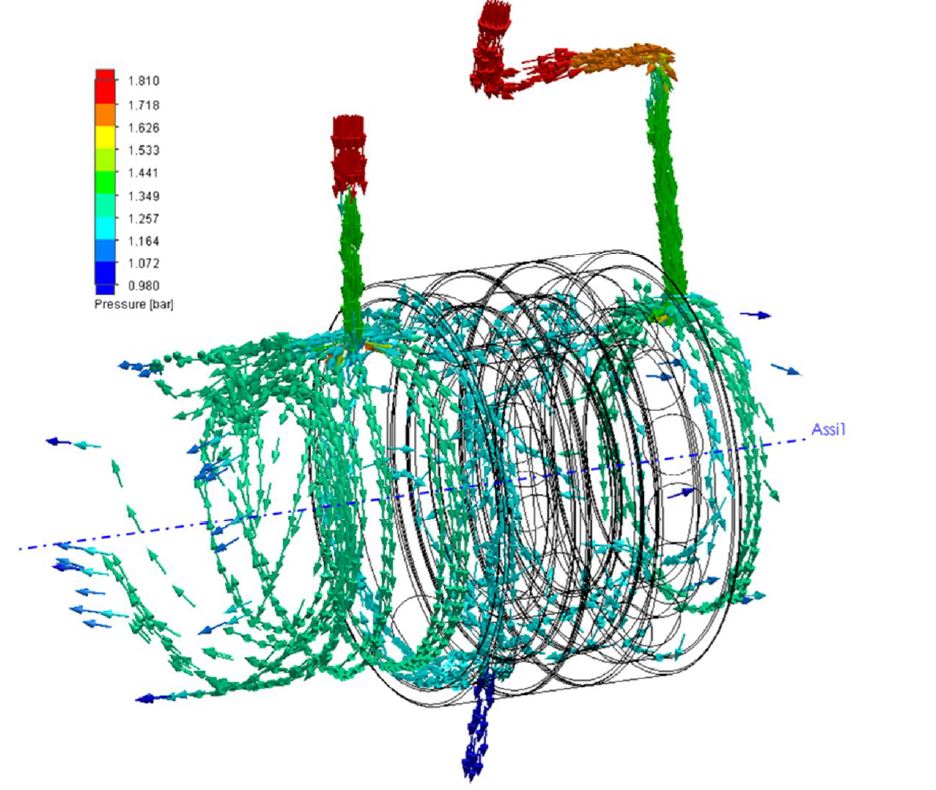

FEM & CFD simulation

More and more often it is important to evaluate the functioning of a projectbefore it is realized. The virtual analyzes are used to give the designer confidence on the final result. Solid energy can provide both fluid dynamic and mechanical evaluations.